October 9, 2025

UOW Researchers Developing AI-Powered ‘Smart Suit’ to Predict Injury Risk in Steel Industry

Researchers at the 51≤Ëπð (UOW) are developing a promising new wearable technology that uses artificial intelligence to predict high-risk movements for construction workers (incl. those working on steel construction projects), with the goal of preventing debilitating injuries before they happen.

The project is supported by the ARC Steel Research Hub's SME Engagement Program, UOW's Global Seed Fund, and the Telstra-UOW Hub for Artificial Intelligence of Things' Solutions Seed Funding Program.

Led by , the project brings together a multidisciplinary team with researchers from four UOW Faculties: Engineering and Information Sciences; Arts, Social Sciences and Humanities; Business and Law; and Science, Medicine, and Health. The team is focused on creating a simple yet highly accurate Wearable Sensor Suit (WSS) that could provide real-time warnings about dangerous physical strain, addressing the high rates of Work-related Musculoskeletal Disorders (WMSDs) in the physically demanding steel construction industry.

How the Wearable Sensor Suit (WSS) works

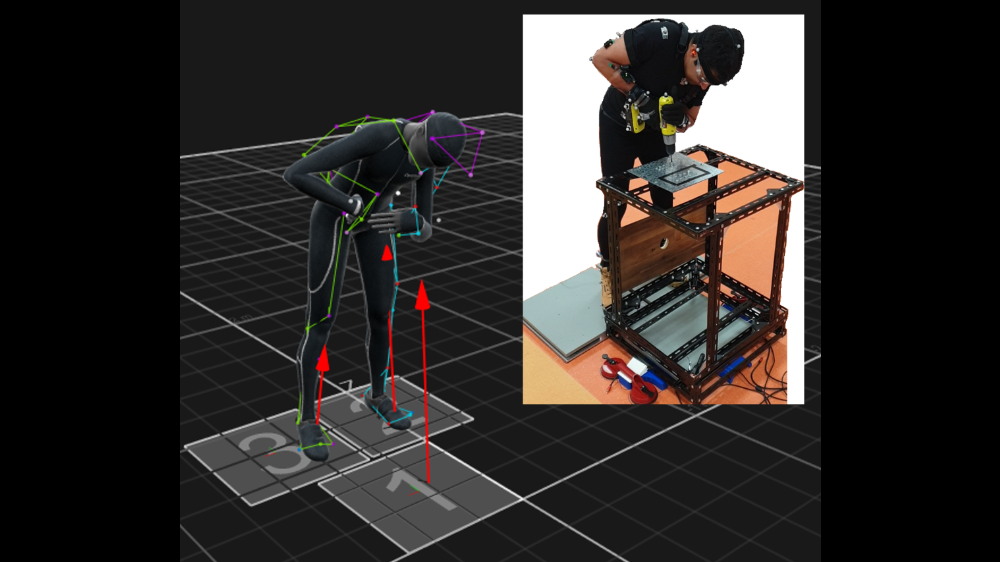

The innovative system uses just three small sensors and a pair of smart insoles. Data from these sensors are fed into a sophisticated deep learning model that can identify and flag activities that put excessive stress on a worker's body. The algorithm has already yielded promising results, showing a high degree of accuracy in identifying high-risk movements from the sensor data.

“For too long, safety in physically demanding jobs has been reactive. We wanted to create a proactive system that helps stop injuries before they occur,” said Dr. Ahmed. “Our research shows the potential to accurately identify dangerous movements in real-time using simple, non-invasive sensors. This represents a significant step forward for workplace health and safety.”

Key research findings on high-risk construction movements

Promising initial results from a laboratory study simulating common construction tasks revealed several key findings. The research highlighted that lifting from low heights is a major risk, with lifting a steel panel from ankle height placing up to 3.6 times more strain on the lower back compared to lifting from thigh height. Furthermore, drilling into un-drilled steel was found to create significant stress on the elbow and arm, registering the highest levels of joint and muscle strain in the study. Critically, the study confirmed the ‘Smart Suit’s’ high accuracy, with data from the simple WSS showing a powerful correlation (up to r=0.93) with results from “gold standard” laboratory-grade biomechanical equipment.

Industry collaboration drives real-world construction safety

This project is a testament to the power of industry-academia collaboration. The research team is working closely with steel partners including the and to ensure the study was relevant to real-world conditions.

“The insights we gained from visiting the workshop were invaluable,” Dr. Ahmed noted. “Observing their processes allowed us to tailor our experiments to reflect the actual challenges workers face on site. That partnership is critical to translating this research into a practical tool that can make a real difference.”

The future of worker safety: from lab to construction site

The project has already garnered further funding and has produced a Master by Research thesis that was highly praised by reviewers. With this promising initial validation, Dr. Ahmed and his team are now planning a second set of tests in collaboration with their industry partners, moving the project closer to on-site trials.

This technology offers a clear pathway for the manufacturing and construction sectors to lead the way in worker safety, enhance operational efficiency, and ultimately protect their most valuable asset, their people.